Submarine pipeline explosions

Roger Alexander

Corrosion Control Technologist

Evidence

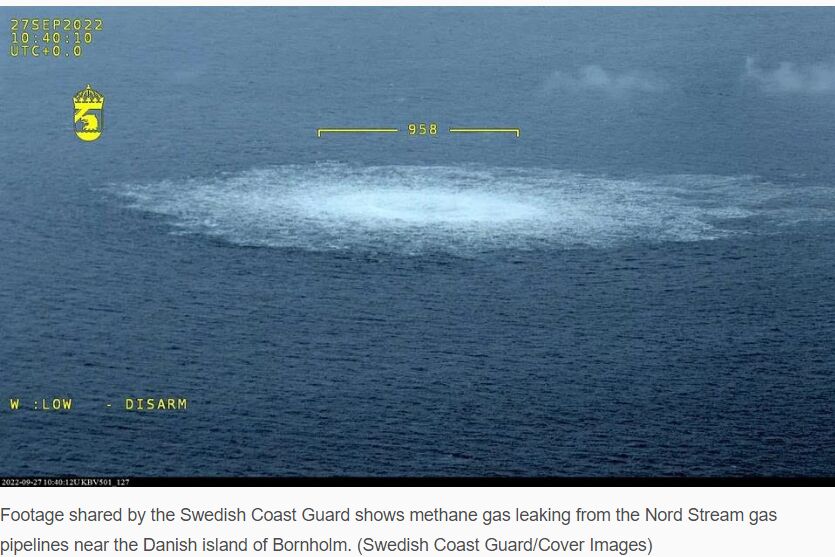

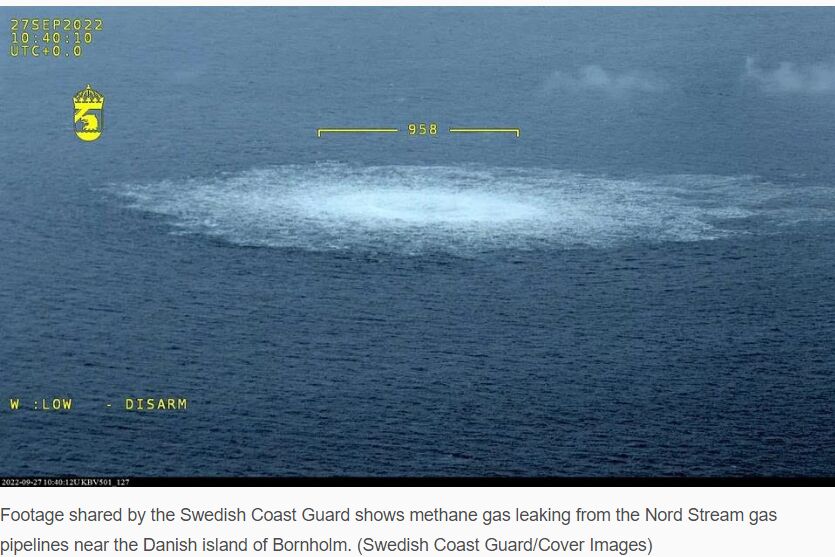

Information about the Nordsea Pipeline failure is all over the media in reports, opinions, photographs and video clips.

The attention of the global public is focused on pipelines but the attention span of the average person is about 20 minutes.

Media stories spread virally to billions of people and in the process get distorted..

A picture is worth a thousand words but pictures can be photo-shopped. Videos can be selected and played out of context to induce misunderstanding.

We must base our conclusions on data, repeatable experimentation and observations from many perspectives.

Fake news cannot be unpublished. It can be denied or refuted but that only increases interest and doubt.

A pipeline is a means of transport that cannot be derailed, have a collision, make a driver error, lose it's way or be held up by traffic congestion.

A buried pipeline causes less environmentl change than roads or rail.

Corrosion is an electrochemical reaction that dissolves metal. I have studied corrosion control of pipelines and facilities since 1970.

I have investigated pipeline failures due to corrosion.

I can demostrate the way that we measure corrosion and have samples of corroision to destruction.

I can present the evidence in this document to any scientist, institution, tribunal or court.

Corrosion can be accelerated by increasing the electrical energy discharged into the electrolyte.

I successfuly investigated accelerated corrosion on two flowlines in the Eastern Division of Shell-BP Nigeria that had leaked several times between the time when they were newly installed and my appointment as ENG18 Corrosion Engineer. I stopped the corrosion and 18 years later had it confirmed that they had not leaked since.#

I detected accelerated corrosion on the export pipeline at Bonny Terminal and was able to prevent a leak. I recently learn that the export pipeline at Forcadas has leaked and put that pipeline out of action for several months. It is likely that this has been caused by accelerated corrosion but a terrorist group are claiming that they blew it up. There are no reports of an explosion and the leak had to be excavated to repair the pipe by a leak clamp that could not have been applied to a burst pipe.

I have many other investigations and case studies that I documented.

Pipelines are resistant to compression from the outside because of their shape. It is the same structure as an architectural arch or an egg that you cannot crush between two fingers at each end. In the case of a submarine pipeline there is the strength of the steel plus the strength of the reinforced concrete weight coating.

Only the operators have the data about internal pressures and variations over time and this is crucial to any investigation.

Pipelines are cleaned and products separated using PIGS that are pushed along by pressure from the pumping station. If the inside of the pipeline has protrusions the pig gets stuck and additional pressure applied. If this pressure is greater than the hoop stress yield the pipe will burst at the weakest points

Pipelines are protected from corrosion by bracelet sacrificial anodes that dissolve to prevent the pipeline steel from dissolving. These are welded onto the pipeline at intervals and are not coated or weight coated. If these are depleted by accelerated corrosion the pipeline steel will be dissolved until this area will not have the strength to withstand the internal pressure and the pipeline will burst

.

There are too many pictures in the public domain to reproduce here.

These show the size of the operation ad the pipes before the weight coating is applied.