CATHODIC PROTECTION NETWORK INTERNATIONAL

74 DALCROSS

BRACKNELL

BERKSHIRE

RG12 0UL

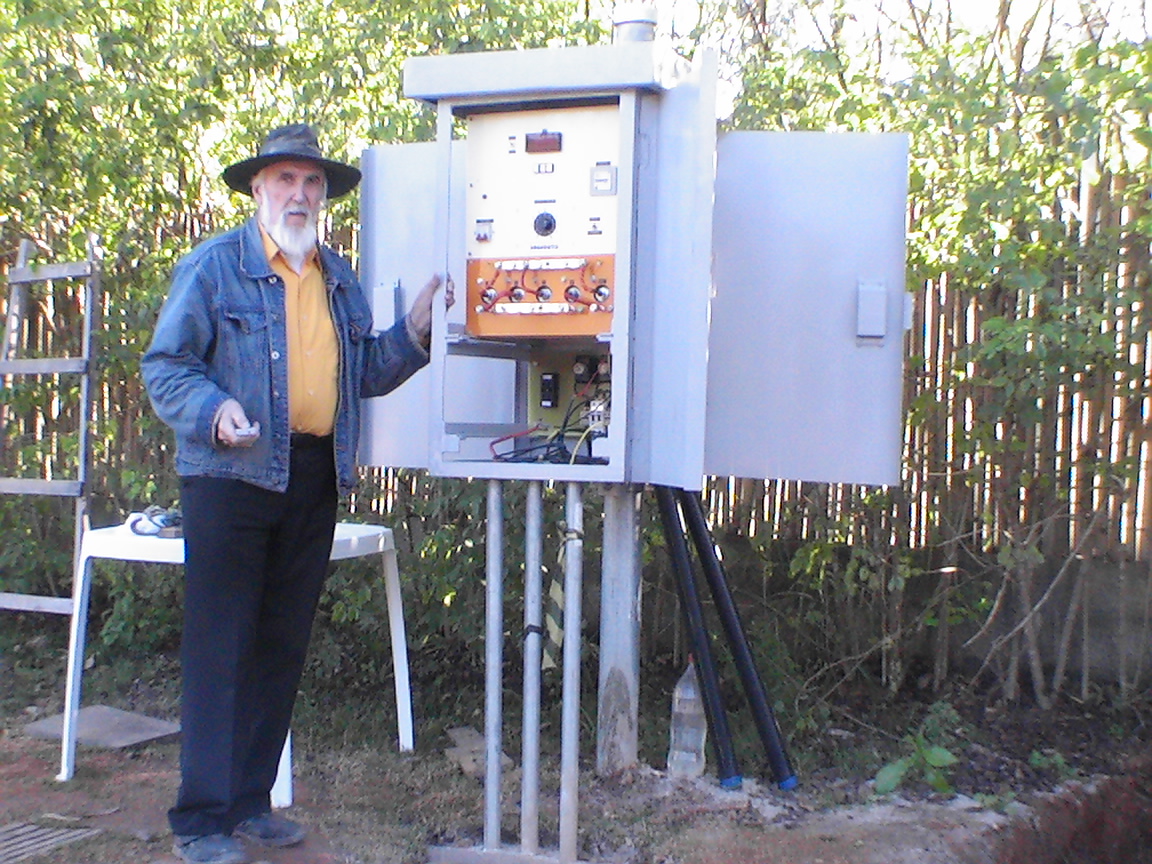

Technotoy

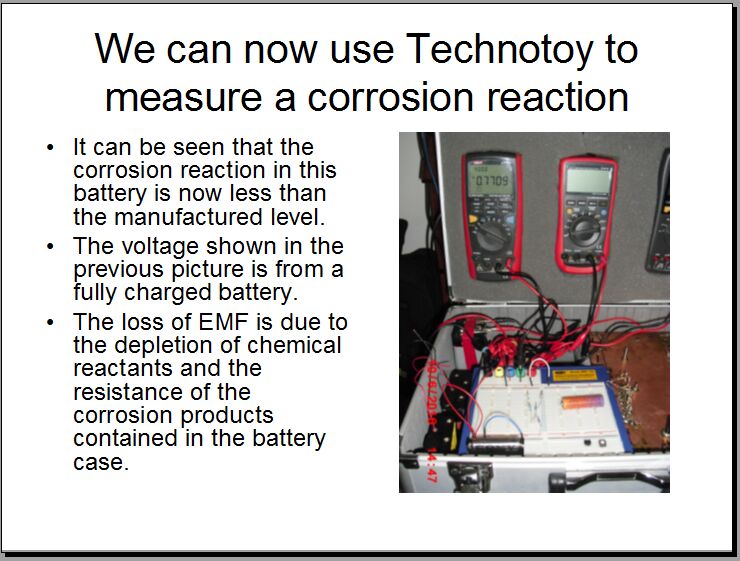

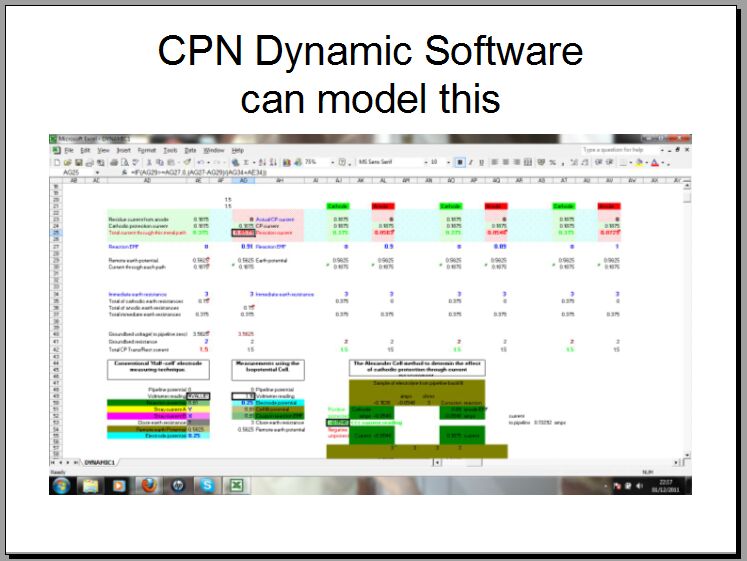

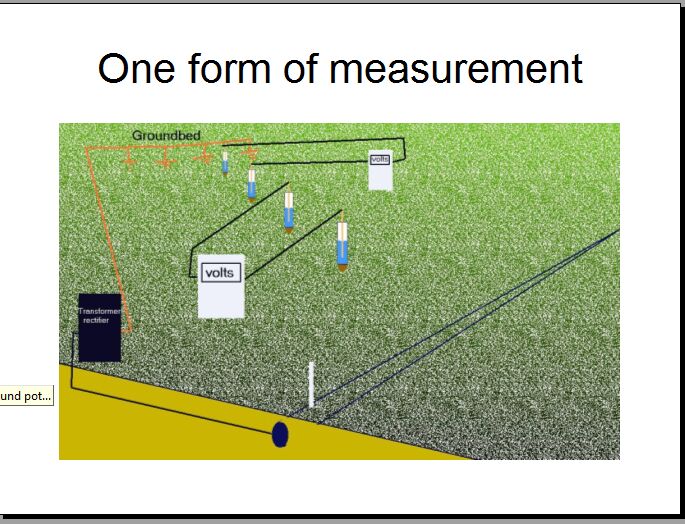

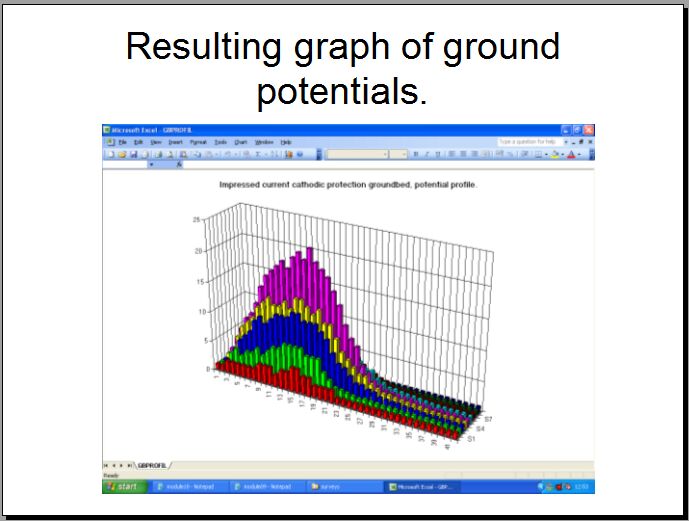

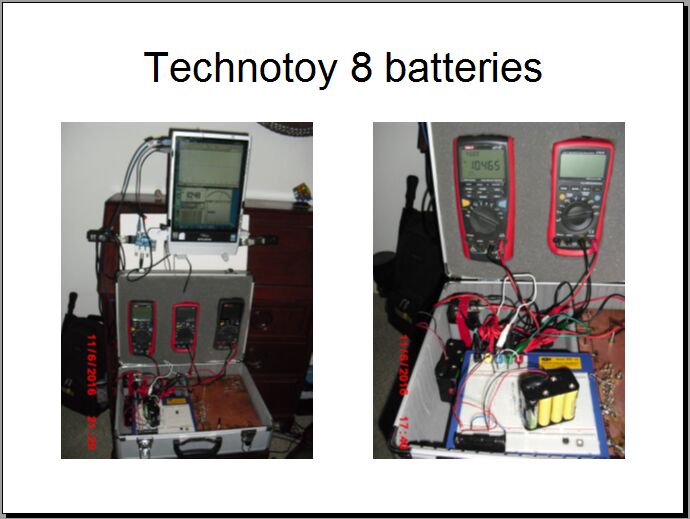

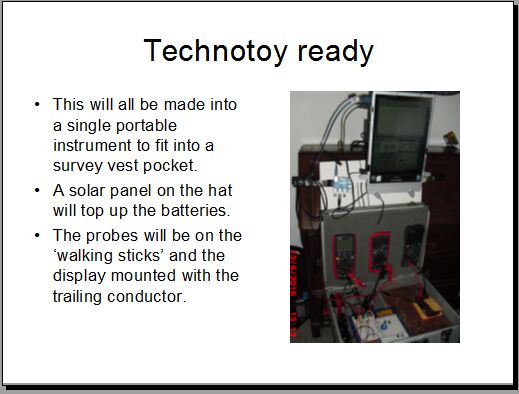

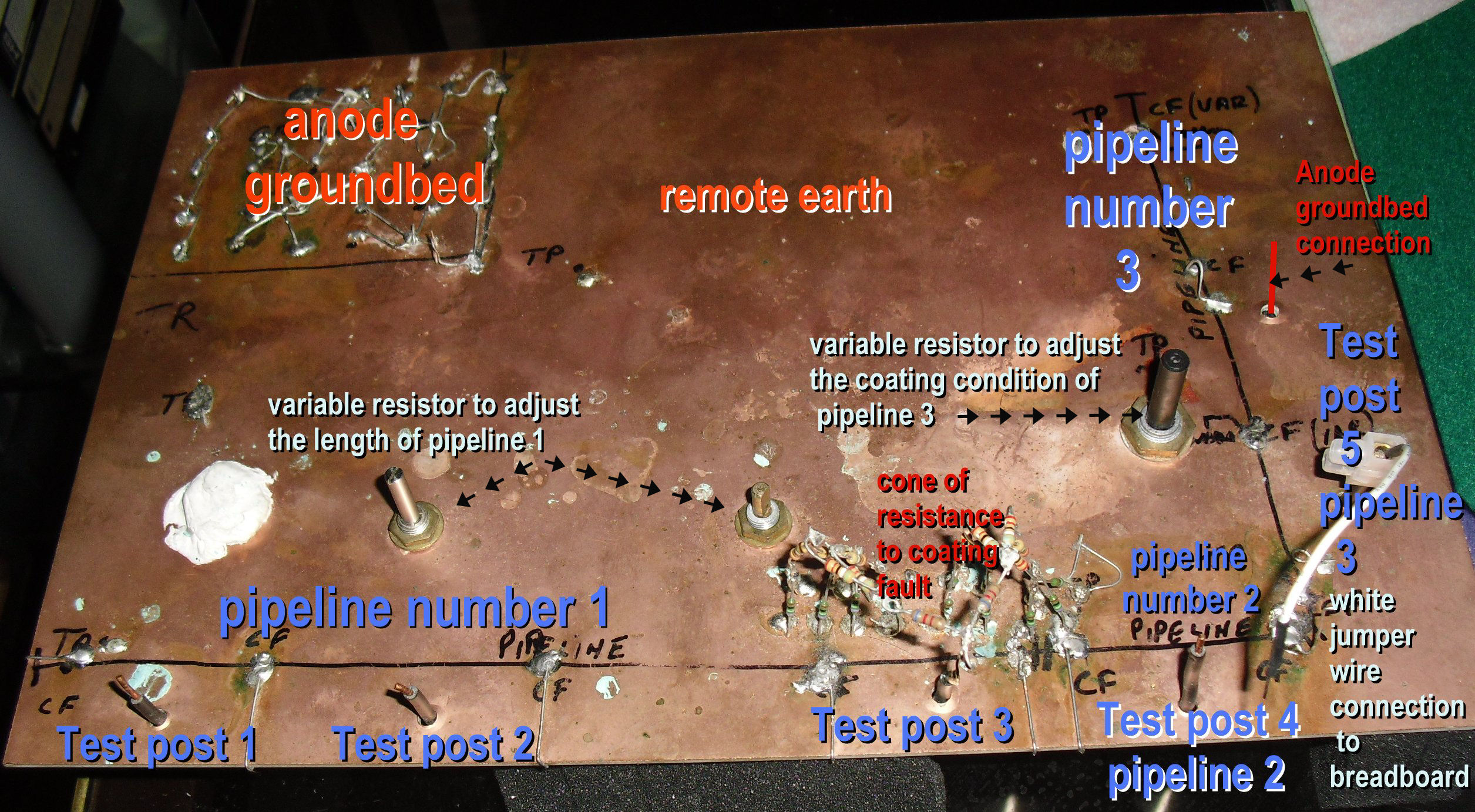

In order to develop software that will predict corrosion on pipelines it is necessary to test the predictions as work progresses. Technotoy is a physical model of the components of a cathodic protection system that incorporates all of the features that I have encountered in field work and have analysed in the billions of data points and information that I have gathered myself and received from others in the past 50 years.

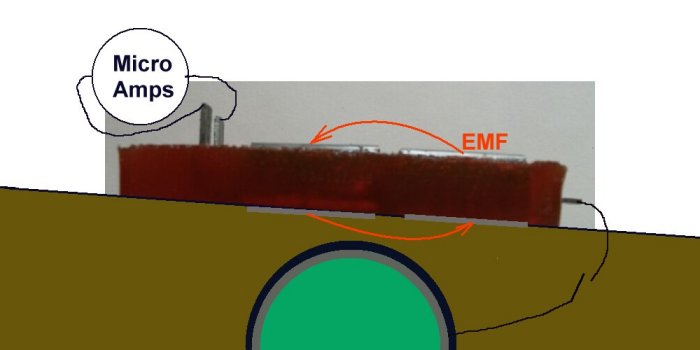

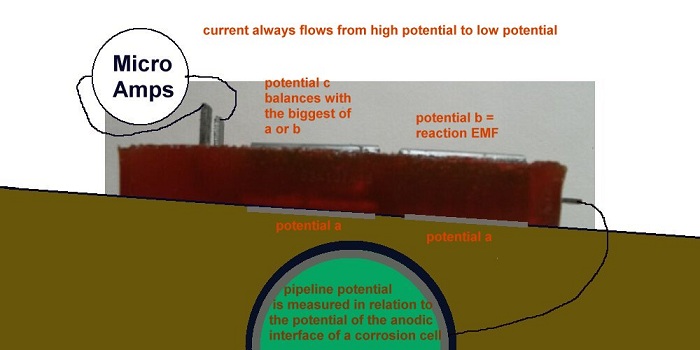

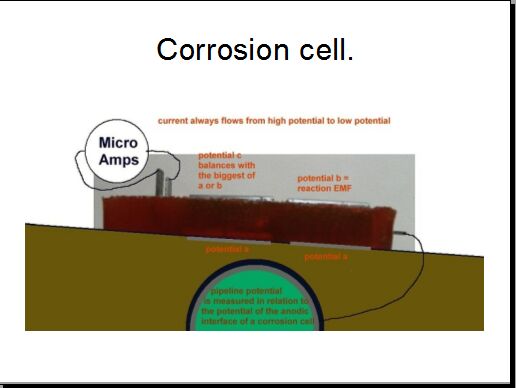

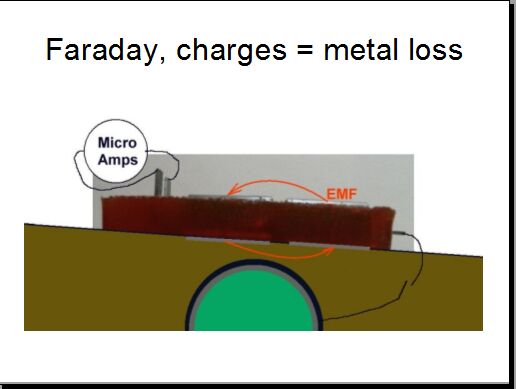

In real life the energy derives from the electromotive force of the corrosion reactions at the interface between the metal and the electrolyte. This is replicated in the Alexander Cell.

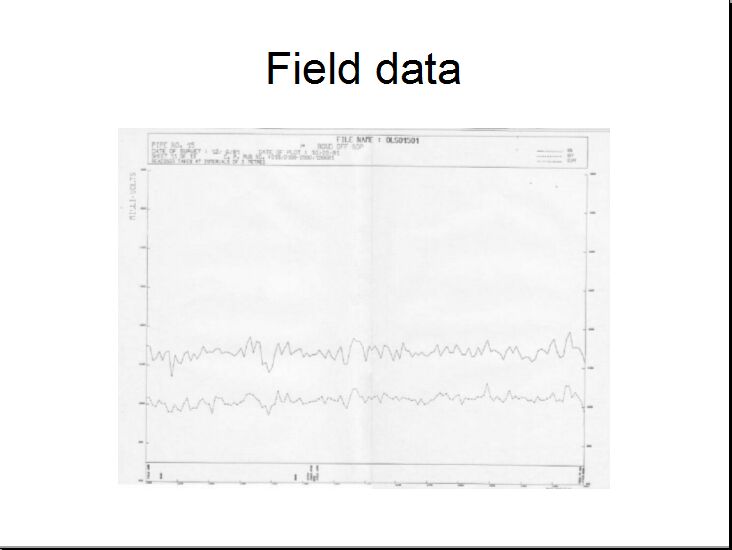

Natural energy flow also comes from sunspot activity, geomagnetic activity and 'teluric effects' in the ground itself, all of which I have investigated in depth.

In addition there is a number of man made sources of energy flow that must be built into the computer model.

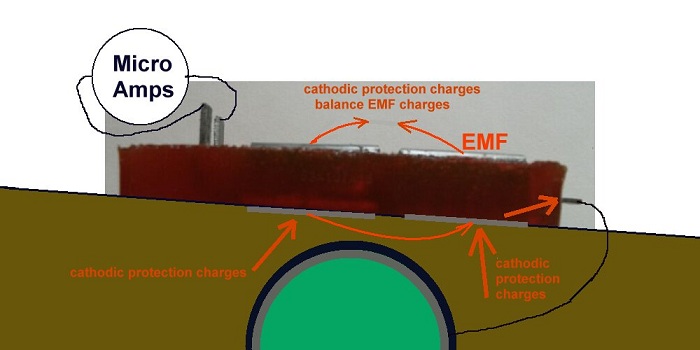

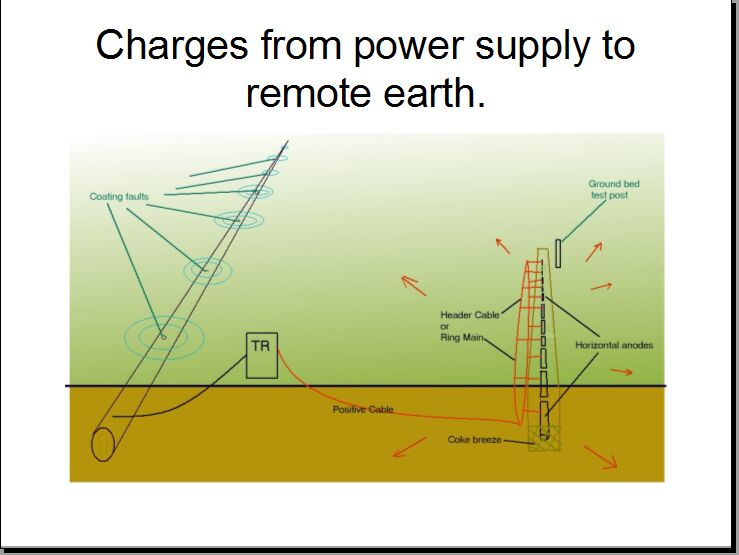

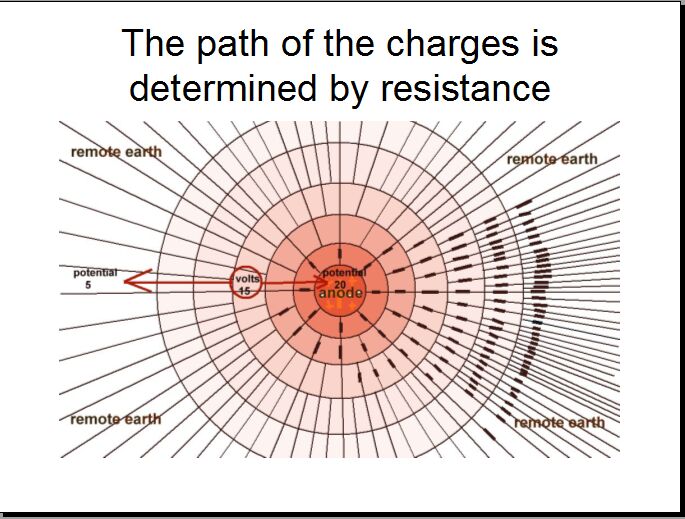

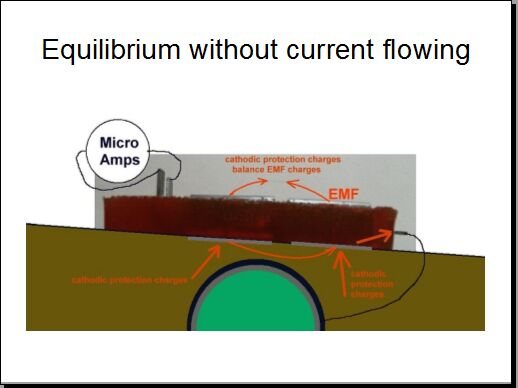

In order to control all of the corrosion reactions on our pipelines and structures we use our own sources of energy that we call transformer/rectifiers and sacrificial anodes that alter the equilibrium at the interfaces and prevent the metal from going into solution.

I built the original Technotoy in 2016 and here are the presentation notes I made at the time. You will note that some of them are wrong and I was hoping that I would get some help in developing this project but nobody else has been interested so I have made little progress since then.

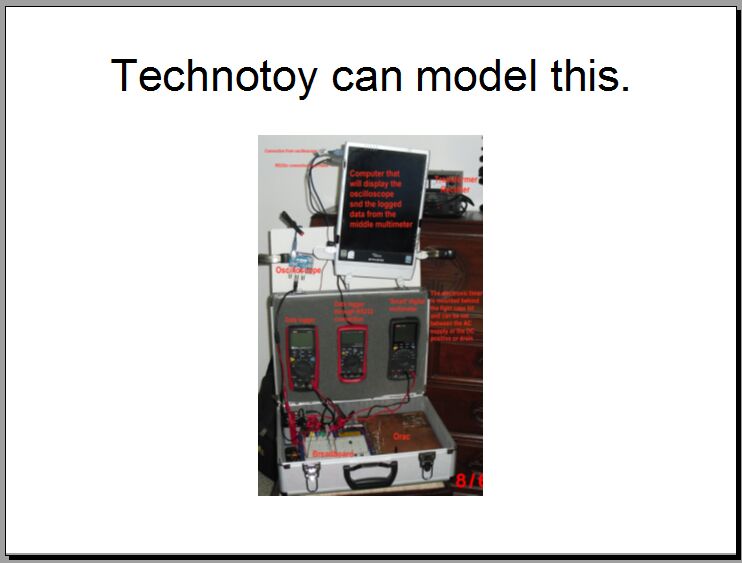

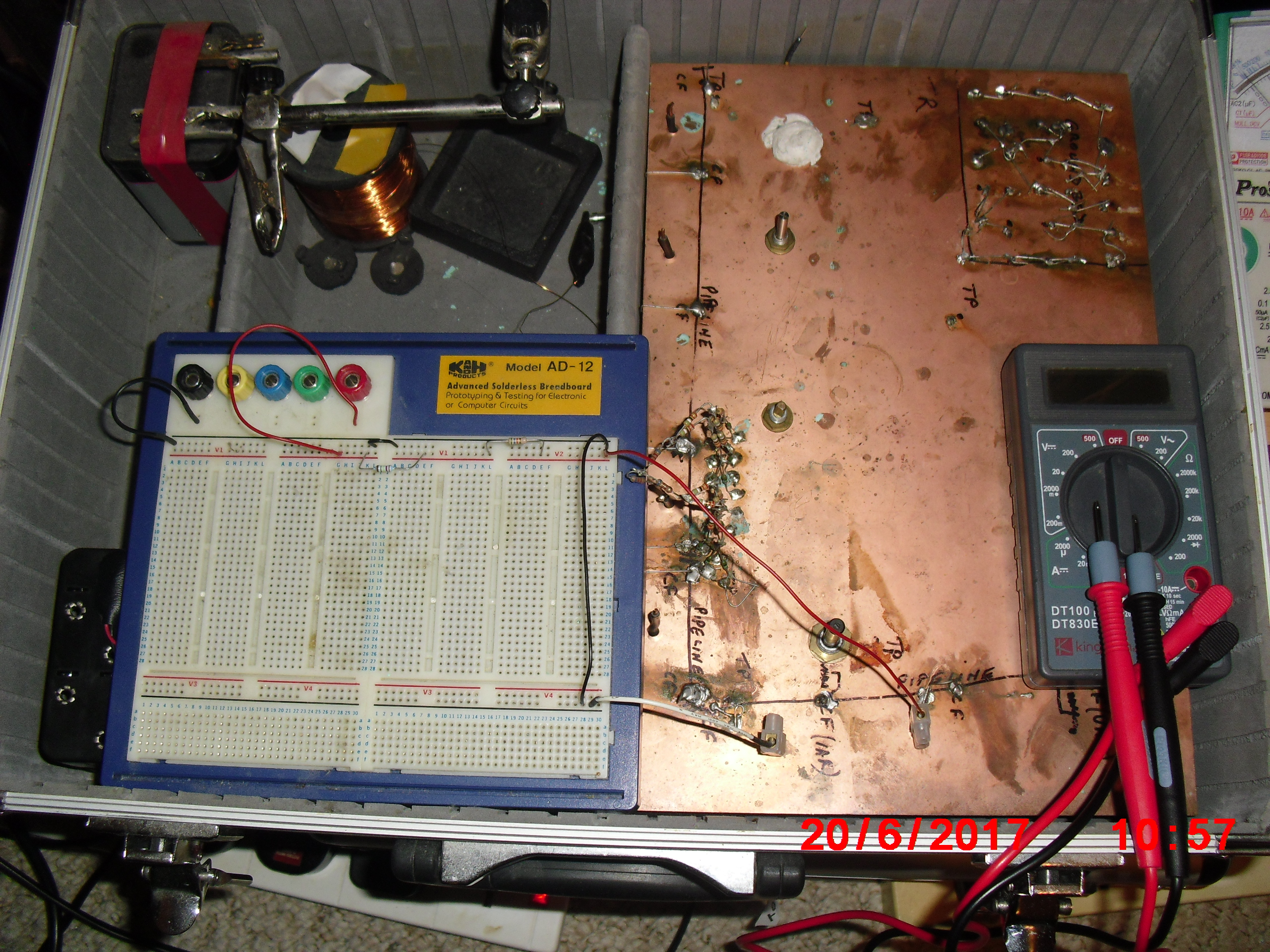

I have built three adjustable power supplies into the latest Tecnotoy that rectify alternating current energy into direct current energy and can apply this at any chosen node. This allows us to apply the Kirchhoff's equations across the system. There are now three more extensions that I will photograph as I add them.

Energy can be fed into or drawn out at a variety of nodes in the circuit.

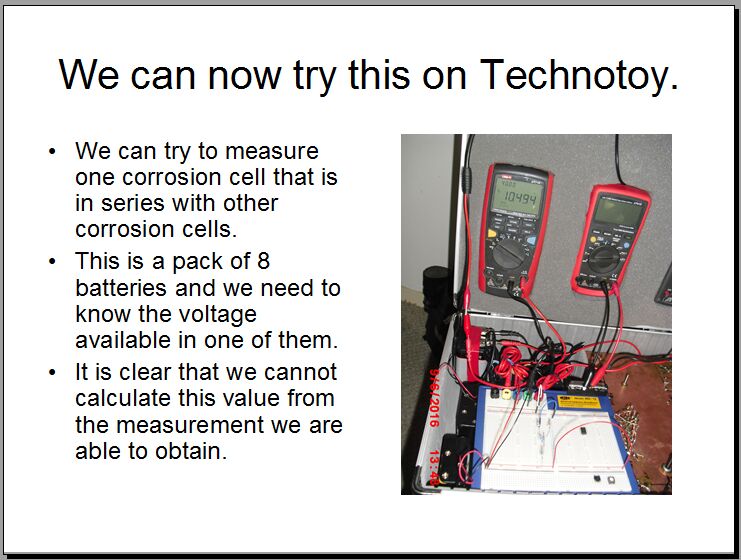

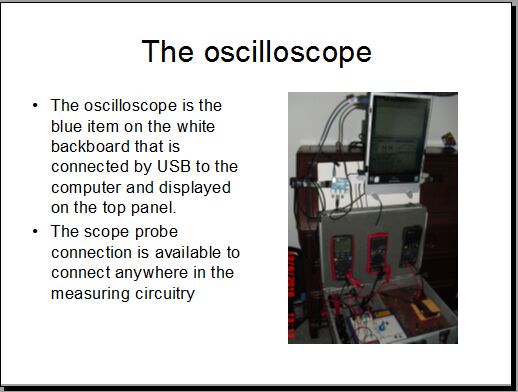

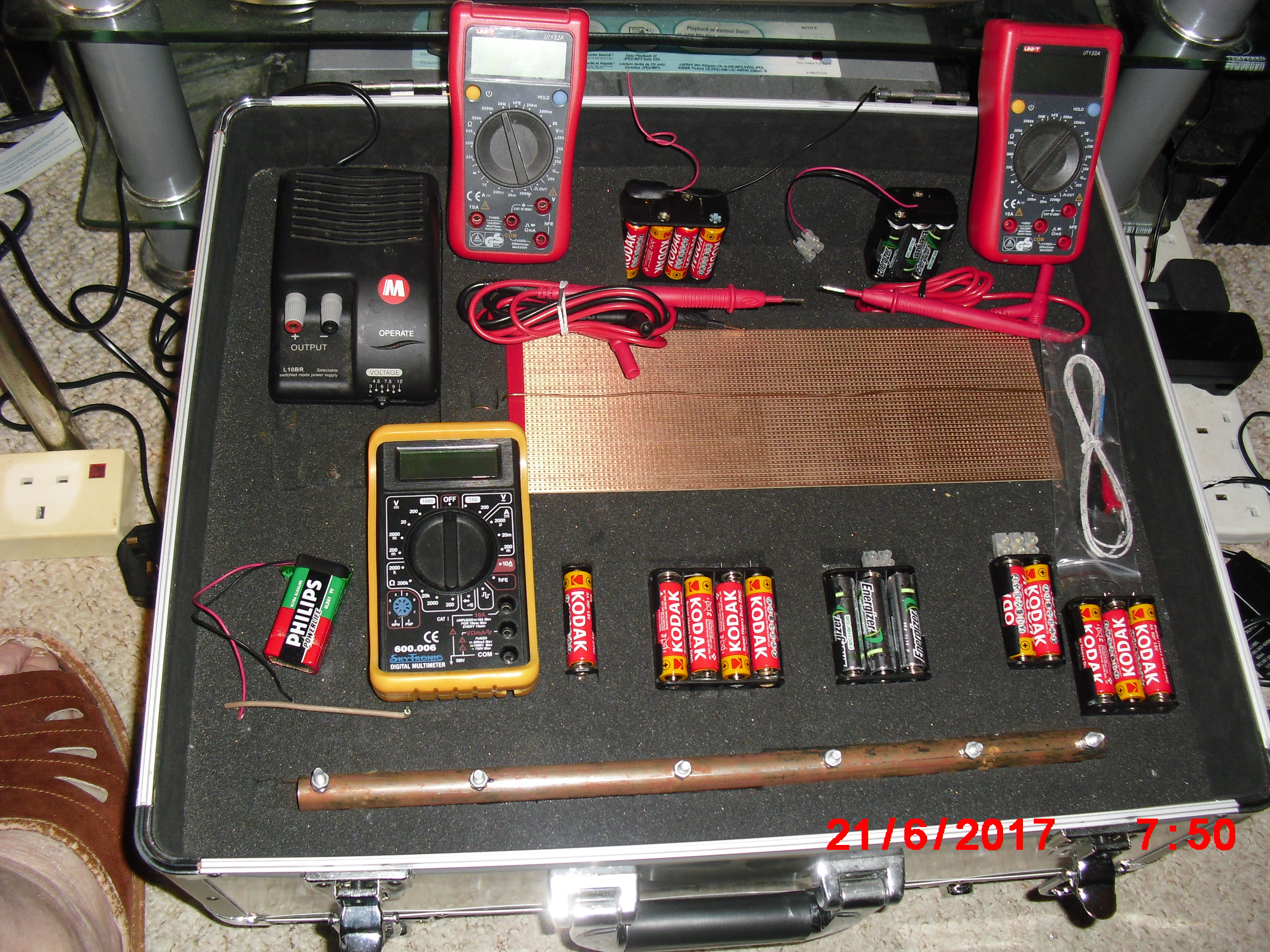

There are now nine multimeters and a digital oscilloscope to measure currents and voltages between a selection of nodes and three PC computers connected to the circuit to enable software development. I have also just bought a CrowPi developers computer kit that I will use at a further stage to write the software.

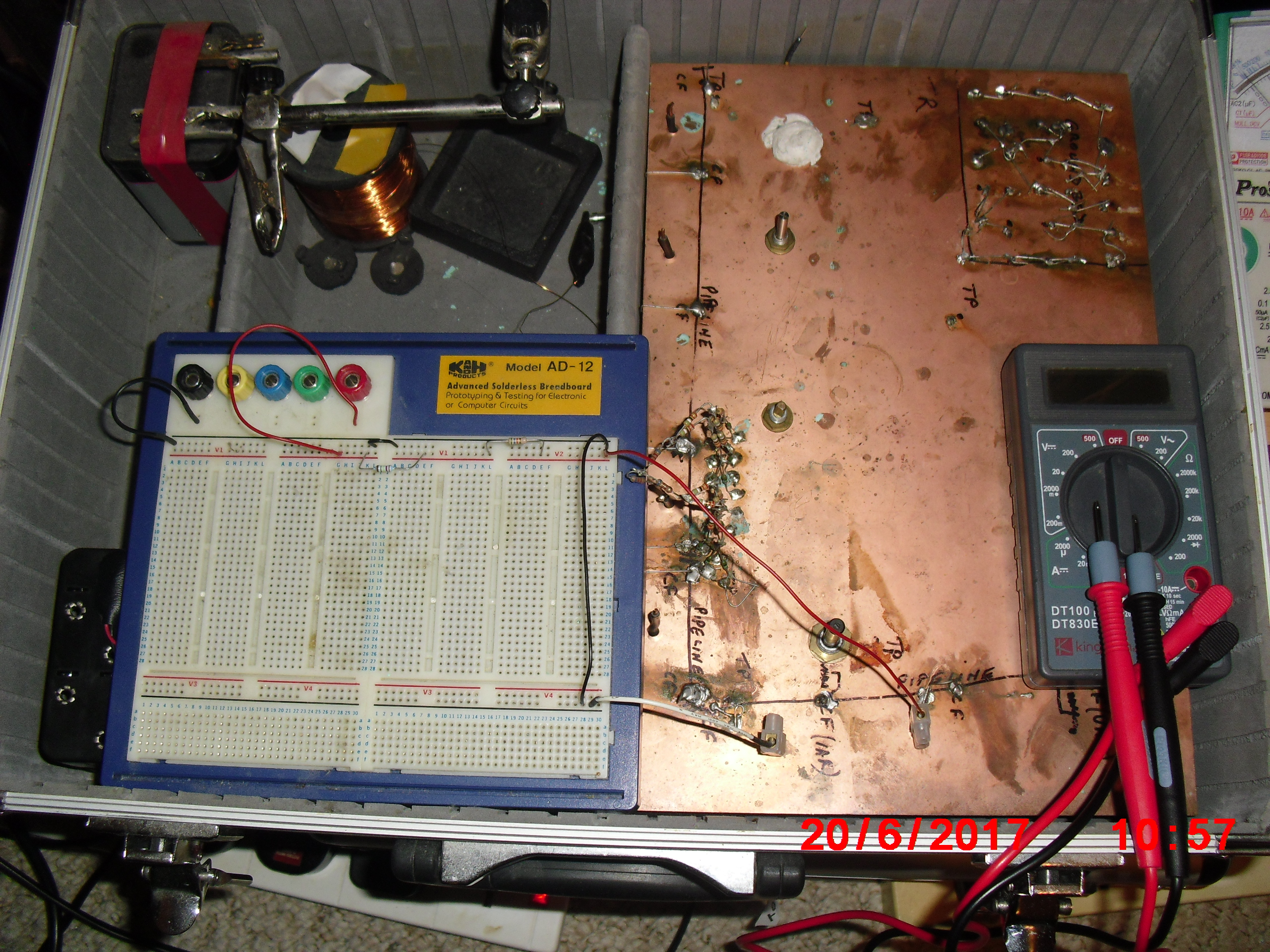

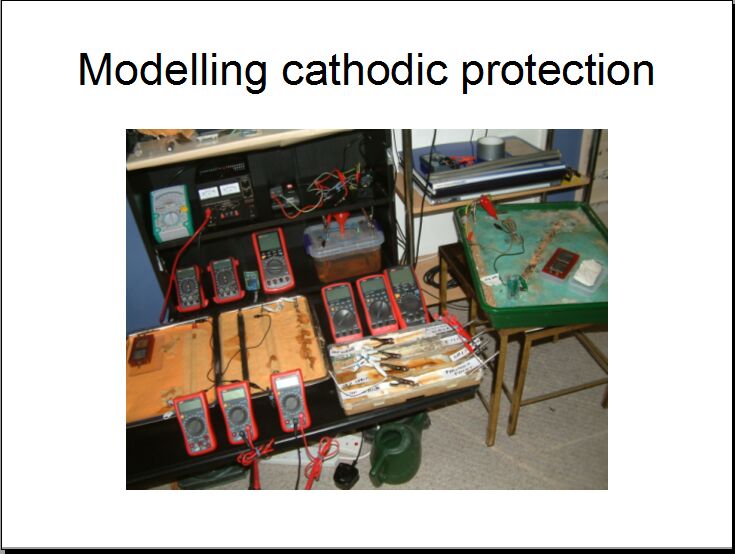

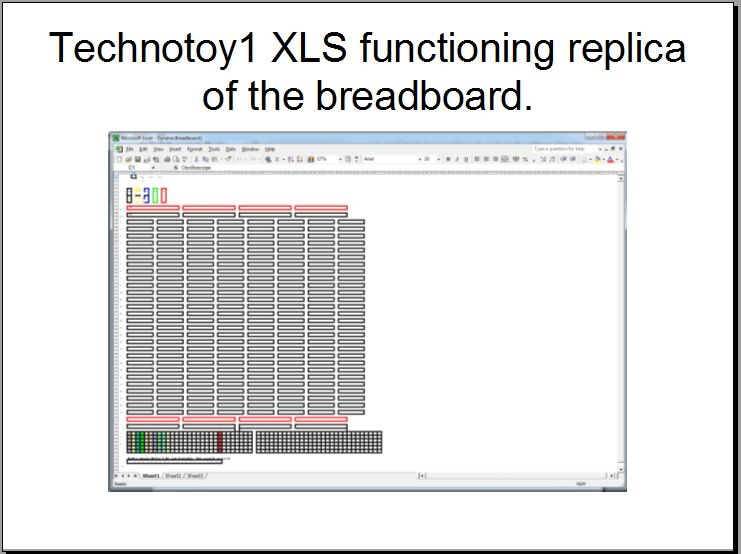

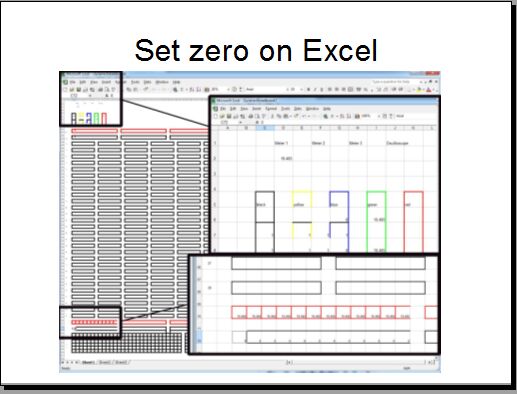

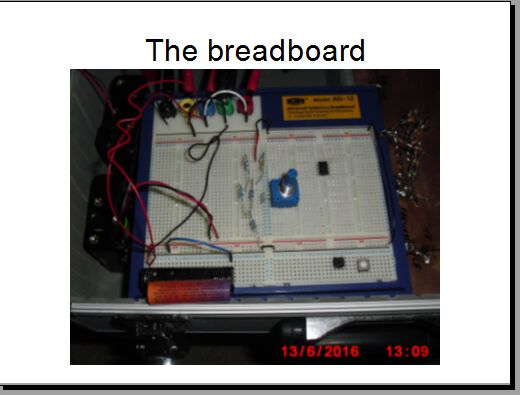

The breadboard is the first stage of modelling using electronic components and dry cell batteries.

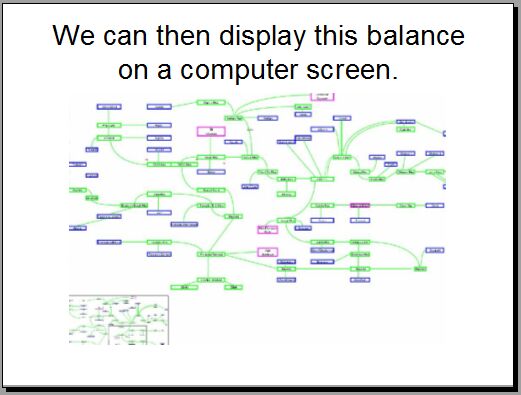

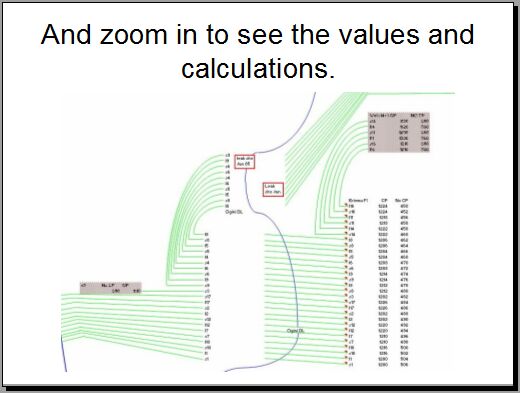

The breadboard is connected to the equivalent circuit called 'Orac'

Orac is connected to 'Orac 2' that is an arrangement of corrosion cells (dry cell batteries) reflecting the effect of CP on a variety of configurations of corrosion cells on a single section of pipeline that can be put under cathodic protection. The batteries can be stopped from discharging current by balancing the electrical pressure from each corrosion cell.

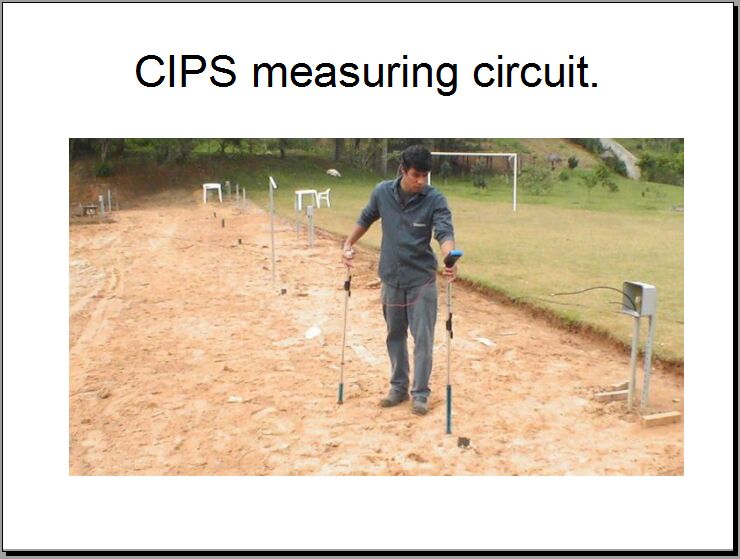

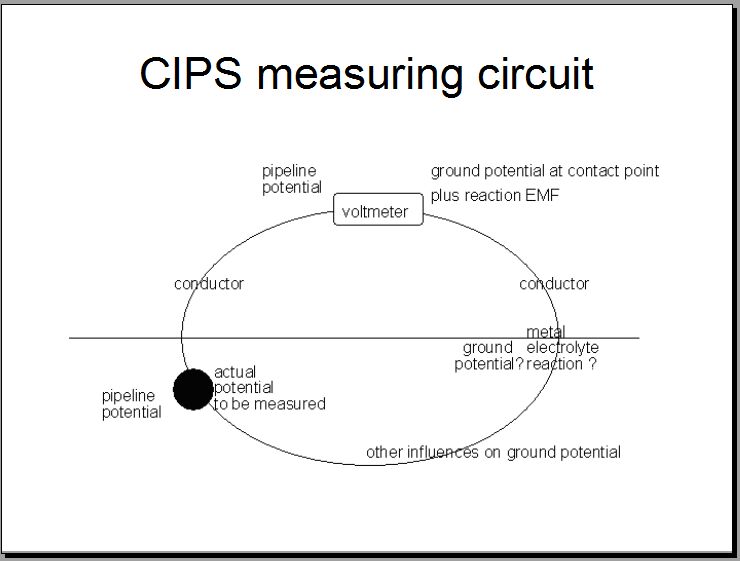

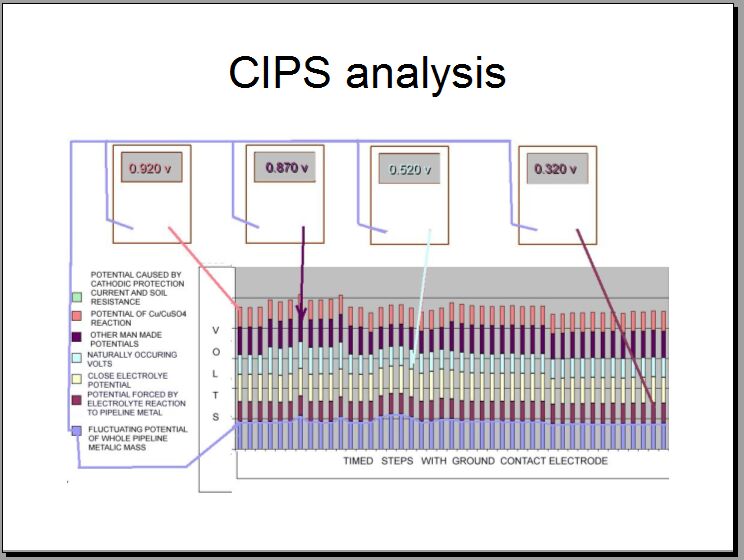

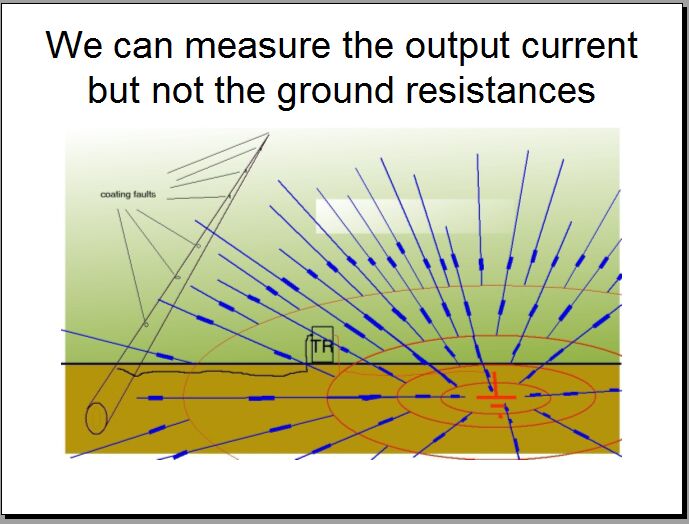

The breadboard can also be connected to a model of two pipelines with coating faults over which DCVG and CIPS surveys can be recorded with the data logger and oscilloscope.(not in the pictures but are to be added)